How To Get Blendall Repair Sticks Out Of Fabric

In this sewing tutorial, I volition testify you how to apply fusible interfacing. You lot will larn what is interfacing, which side of the interfacing is fusible, is fusible fleece the same as interfacing, how do you clean fusible interfacing from an iron, etc.

What is fusible interfacing?

Fusible interfacing is a very interesting material used for sewing, quilting and craft projects with all kinds of fabric. You fuse information technology to the incorrect (unseen) side of fabric to give information technology additional strength, support or required shape. It'due south unremarkably used to stiffen collars and cuffs, reinforce facings and buttonholes, strengthen waistbands in garment construction. It's widely used in sewing bags and purses, it'due south as well essential for quilters, it can be used for preventing cloth fraying, etc.

Attending! If y'all like the video format, at the bottom of this mail service, expect for a YouTube video version where there is a step-by-stride tutorial on how to use fusible interfacing. For a more complete picture, I recommend exploring both versions.

Types of fusible interfacing

Before applying the fusible interfacing nosotros have to know what type of interfacing is suitable for the particular projection and for the textile.

When I started to sew together 30 years ago I had only One type of fusible interfacing available to me (well, maybe at that place were unlike types so also, but they were not available for home sewing).

Now I take at dwelling house maybe 20 different types and most of the time when I need interfacing information technology turns out I don't have the exact type that I need so I take to purchase it.

All types of fusible interfacing accept a rut activated adhesive material on one side or on both sides which bonds to the fabric when ironed. Fusible interfacing tin have different structure and thickness in social club to be used with different fabrics.

So, what are the types of fusible interfacing we can use for our projects?

Notation: Some of the links on this page are affiliate links. This means I will receive a commission if you social club a product through one of my links. I merely recommend products I believe in and use myself.

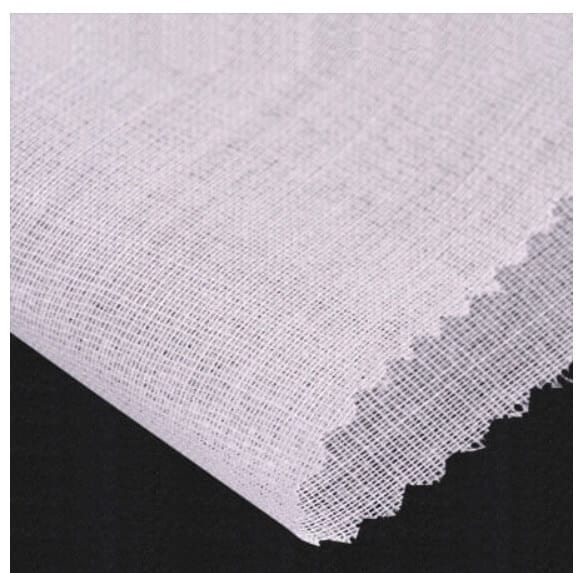

- Not-woven fusible interfacing is the about common blazon everybody uses. It's a pure production of the chemic industry – information technology's not material, information technology will not unravel. Ordinarily, it has no grain, and because of this, information technology tin can be cut in any management which is keen considering you lot can utilize every bit of it in a very economical way. But sometimes it has the grain though and then manufacturers advise to cut information technology according to the grainline. Information technology doesn't have any stretch, and can exist used with any woven cloth. I don't recommend using it for knit textile unless yous want to reduce cloth stretch.

2. Woven fusible interfacing is a kind of cloth – it has a lengthwise and crosswise grain. It's fabricated from warp and weft fibers interwoven together. It'south non widely used in dwelling sewing. Most of the time they get in non stretchy only sometimes it can have some stretch property also. This type works well with woven fabric.

3. Knit fusible interfacing is stretch like knit fabric and used mostly for stretch knit fabric. It's made past knitted fibers together.

4. All the in a higher place types of fusible interfacing tin be further classified every bit lightweight, medium weight and heavyweight.

Lightweight is used with lightweight fragile fabrics to add strength and immovability.

Medium weight works for a wide variety of fabrics and heavyweight is slap-up for adding structure to purses or brims of hats.

Generally, the heavier the textile you are using, the heavier the interfacing you need. Nonetheless, your interfacing should exist slightly lighter weight than the fabric you are using.

Fusible fleece. Is fusible fleece the same equally interfacing?

Yep, fusible fleece is some other type of interfacing. It's quite thick, thicker than regular fusible interfacing, 100% polyester fleece with adhesive on one side. It's used for the fabric to hold a specific shape. Information technology easily adheres to fabric.

Fusible web vs. fusible interfacing

I oftentimes hear these questions: What is fusible web? What is fusible web used for? Is fusible web the same as interfacing?

I think fusible spider web is some other type of non-woven fusible interfacing which has adhesive fabric on both sides and glues 2 layers of cloth together.

Usually, not-woven interfacing looks similar newspaper with glue dots. Fusible spider web is a little bit different – it looks like a web, really. Information technology melts from the hot iron and adheres ii pieces of fabric together. Fusible web is intended to be permanent and tin't be removed from fabric.

Sometimes information technology has paper backing that you demand to peel off earlier using. It's available in diverse weights also.

Fusible web is used mostly for applique and for hemming.

✅ Related tutorial: How to use fusible interfacing for confront masks

How to fuse interfacing

It seems so easy to fuse interfacing. Commencement I want to show you the common way (but not necessary the best way) to practise it and after that, we will encounter what problems y'all may have in the process and how we can solve those problems.

- Pre-wash the cloth if necessary and press it so the cloth is shine and flat.

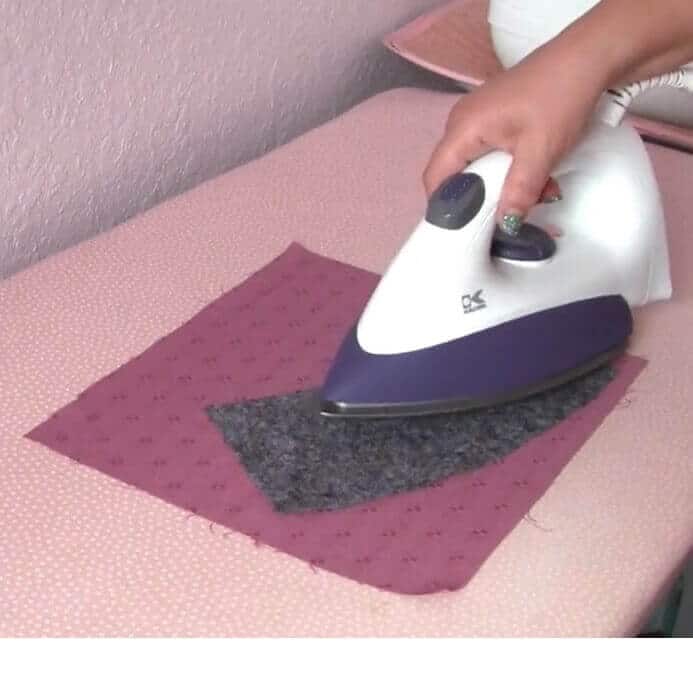

- Identify your fabric on the ironing board wrong side up.

- Observe the adhesive side of the interfacing ( I'll show later how ) and place the fusible side of the interfacing on the incorrect side of the fabric.

- Press with a hot iron. Employ firm, even pressure and go along the iron in place for a few seconds, like ten-15 seconds. You can use steam or employ but dry heat – equally recommended past the manufacturer.

- Lift the atomic number 26 and place it dorsum downward in a new position, slightly overlapping the previous areas. Echo until all areas of the interfacing have been fused to the material. Do not slide the fe beyond the textile, as you may shift the layers of material and interfacing and this can cause distortion.

- Once you've pressed from the interfacing side, flip the fabric over and repeat from the right side of the textile to ensure a adept bond.

- Bank check if interfacing has adhered properly and if you run across that information technology'due south not glued well, press information technology again.

- Don't employ interfaced pieces while they are still warm because interfacing can be distorted. Let it cool downwards.

Seems easy, right?

✅ Related tutorial: Iron ownership guide

The other common mode to exercise it is to attach the agglutinative side of the interfacing to the wrong side of the fabric and place them on your ironing lath with fabric correct side up. Printing with a hot iron. You can do this if you are afraid the interfacing volition stick to the iron. I will talk about this in detail later.

In most cases, information technology'southward advisable to use a pressing cloth and sometimes information technology'southward absolutely necessary if y'all are using some special material like silk or leather.

Hither I would similar to show you something cool. Practise you know what I employ as a pressing cloth? 100% silk organza! It's a perfect material – information technology withstands the hottest fe temperature and steam and I can see very clearly through it when I am ironing.

Sometimes you can fuse the interfacing with a steam iron and other times y'all volition need to plow steam off and use dry out iron — follow manufacturer's instructions (as they say). And where do you discover those recommendations? Well, information technology's not always possible. I am used to keeping the newspaper from a manufacturer with a piece of interfacing. If you don't have any instruction for your particular interfacing – just use a pressing cloth and printing through it with steam. It ever pays to exam the fabric, more about this later on.

Fusible interfacing problems

Now let's see what can go wrong.

1. Fusible interfacing not sticking

Some finishes applied to the fabric in the manufacturing process can foreclose fusible interfacing from adhering to the material. Effort to pre-wash the material before starting your projection.

It can be merely just considering your iron is not hot enough and you just need to keep the iron longer on the material. Most times nosotros need to put the temperature on the "wool" setting. But if y'all are using a pressing textile then you can put a heat setting slightly higher.

Don't think that the hotter temperature is always better for fusing the interfacing. Sometimes an iron too hot burns the glue off or glue melts completely and your interfacing won't stick. Again, information technology always pays to examination.

It can also be because the blazon of interfacing you want to fuse is not suitable for your fabric.

Is your fabric very textured? The adhesive will non stick well to the textured fabric. Use sew-in interfacing instead of fusible.

Is your material glace? The adhesive will not stick well to leather and vinyl so you tin can try to keep the hot iron longer on the fabric.

2. You lot didn't find the adhesive side of the interfacing and the glue stick to the iron, not to the fabric.

Which side of the interfacing is fusible?

Usually, if you look at fusible interfacing really closely you will discover specks of glue on the fusible side of the interfacing and sometimes you can tell the fusible side past the slightly bumpy texture of the adhesive. The fusible side of interfacing has a slight shininess from the glue.

But notwithstanding, everybody guesses wrong from time to fourth dimension and makes a mess on the iron.

How do we solve this problem?

Easy – marker it: once the adhesive side is identified, identify a piece of a painter'south tape on the adhesive side of the interfacing when y'all accept plenty light and you conspicuously can see the shiny gum and have information technology off correct earlier pressing. You can use the painter'due south tape to mark the wrong side of the cloth also (when the departure between right and wrong sides is not obvious).

How do you make clean fusible interfacing from the atomic number 26?

There are many products for cleaning irons. I similar the best this one: Faultless Hot Atomic number 26 Cleaner. Cheque the video below if you want to see how it works.

3. Small-scale pieces of the fusible interfacing glued to the iron or to the ironing board.

Well, you meliorate be careful and protect your cloth and ironing board from any excess adhesive.

Apply a pressing cloth to preclude getting the glue on to your iron. And place a flake slice on the ironing board underneath your fabric.

You tin can too utilise parchment paper – it doesn't' stick to the interfacing. Place it nether your fabric on the ironing board or above the interfacing to preclude information technology from sticking to the board or to the iron.

How do you lot remove interfacing glue from the ironing board?

There is no guarantee you volition be able to remove it from the ironing board especially if yous used fusible web. But you lot tin can endeavour to do this:

Dampen a slice of scrap fabric and identify it on pinnacle of the adhesive left behind on the ironing board. Press with an fe on the highest temperature and steam settings. If something else volition exist left, attempt to use rubbing alcohol to rub the remaining glue. And if all fails, make a new cover for your ironing lath.

4. Fusible interfacing tin can't be used with some fabrics or they require some special attention.

Fabrics that tin can't be safely ironed like fabrics with nap (velvet and fur), sequins and metallic textile, some types of vinyl, laces, mesh and some sheers are better interfaced with sew-in interfacing because they can be ruined past the hot temperature required to fuse the interfacing.

But sometimes I use the fusible interfacing with vinyl and leather.

5. Sometimes fabric can be distorted or wrinkled.

Use an iron temperature that is suitable for both the cloth and for the interfacing.

I have only used fusible fleece for the showtime time to make a lined zippered pouch and when I tested it on scrap 100% cotton fiber fabric it was all wrinkly on the material side. I placed it glue side upwards and and so fabric on top and ironed with a dry fe on cotton setting. The piece got wrinkled all over fifty-fifty if I used a pressing cloth. The reason for this is the fe temperature – fusible fleece needs to be pressed on lower settings than the cotton fiber. Just keep pressing longer with the lower iron temperature.

half-dozen. Fusible interfacing puckering.

Don't glide the fe – simply press. Utilize firm, even pressure and keep the fe in identify for a few seconds, similar 10-xv seconds.

7. Interfacing melts or you harm your fabric.

The iron temperature is also hot. Put the atomic number 26 temperature on the "wool" setting and use a pressing cloth.

Other useful tips and tricks

ane. Practise a test before applying the fusible interfacing to your project then y'all can see how your cloth fuses to the type of interfacing y'all take chosen. Use a chip slice of textile for this. If y'all see that the cloth becomes as well stiff or the interfacing melts you tin can change the interfacing or temperature settings of your iron.

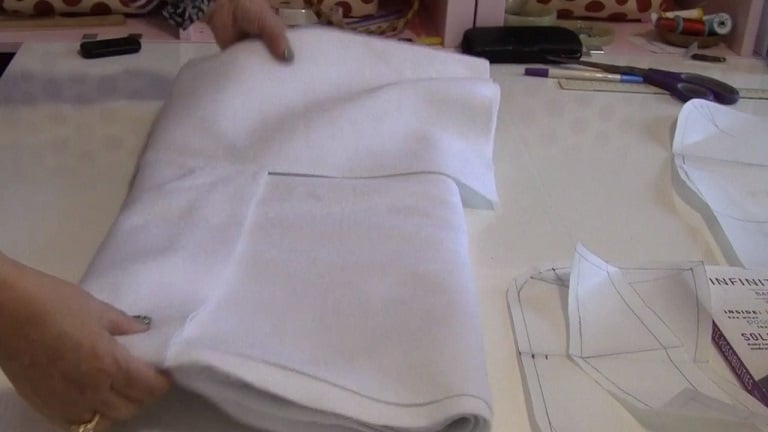

ii. For garment sewing – usually, we cut blueprint pieces so cut coordinating pieces from fusible interfacing.

I do it a little fleck differently – I fuse a large piece of interfacing to the fabric and only afterwards that cut blueprint pieces. It's not actually the economical way to use interfacing considering you will have to identify pattern pieces in accordance with the grainline of the fabric. But it saves so much time!

iii. Tin you wash fusible interfacing?

Sometimes manufacturers advise to pre-launder ( and therefore pre-shrink) fusible interfacing. Don't be agape to practice so – the water will non dissolve the glue! Put it in hot water, let information technology sit there 5 minutes, have out, gently clasp to remove excess h2o and let information technology air dry afterwards. Information technology'due south not necessary to pre-wash every interfacing simply some of them really need to be prewashed.

The interfacing will stay fused afterwards y'all launder your garment or quilt, inside reason. If you washed 1000 times then it may come apart of form.

four. Can you stitch through fusible interfacing?

Yes, you can run up through fusible interfacing. It will be no trouble for lightweight and medium weight interfacing only if you use heavyweight one you lot may need to change your needle for a bigger size (for example it's necessary if y'all are using fusible fleece which is thick).

Sometimes if you are using fusible web, melted glue tin mucilage up your needle. There are special needles that go through mucilage without whatsoever problems – not stick Teflon covered needles. They accept an anti-agglutinative coating, move through the sticky stuff more easily than regular needles and don't get fuss balls usually.

But if you are using a regular needle you may demand to clean it equally presently as you finish stitching.

five. How practice you remove fusible interfacing from cloth? Can fusible interfacing exist removed?

It may happen that you fused wrong pieces. It happened to me – I needed to fuse interfacing to my skirt's yokes and I fused one piece to the wrong side and some other piece to the right side of coordinating blueprint pieces (yokes) because the difference between right and wrong sides was not big. To preclude this use a slice of painter'south tape and marking the wrong side of the material with information technology (see above)

Only if information technology happened, most of the fourth dimension you have no pick but cut the pieces over again. Interfacing is supposed to attach to the cloth permanently.

Only sometimes nosotros can remove fused interfacing if you lot didn't put it properly in the showtime identify.

6. Fusible interfacing typically comes in white or black, so it won't show through the dark or lite material for your sewing project. I have never seen colored fusible only on a manufacturer'southward website, I constitute besides blood-red, blue, green, pink interfacing so I guess we may encounter information technology for sale for home sewists also.

vii. Does fusible interfacing foreclose fraying?

Yes, fusible interfacing tin can terminate the textile from fraying very well. That's why it's actually proficient to utilize with applique.

8. How to choose proper fusible interfacing for your projection

Ane thing to consider is the properties of your fabric. It seems obvious that for lightweight fabric nosotros choose lightweight interfacing and for heavyweight fabric, nosotros chose heavyweight interfacing. They say that interfacing has to exist lighter weight than your fabric (not heavier).

But it's not always clear how to practise it. Is fusible fleece heavyweight interfacing? It certainly is thicker than the cotton we desire to employ it for. And whatsoever heavyweight fabric is certainly heavier than any heavyweight interfacing. It seems to me interfacing doesn't have any real weight. I can see the dissimilar amount of stiffness when I impact interfacing. Does information technology mean that the stiffer the interfacing the heavier it is?

For example, I have this stretch interfacing and this piece of knitted jersey silk. Which one is heavier? Can't be sure.

So how to choose proper interfacing in this situation?

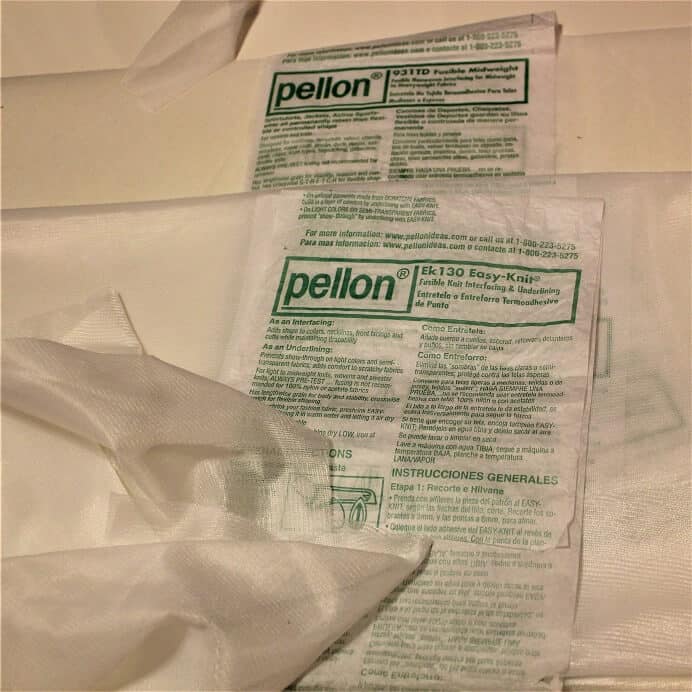

I use the manufacturer's instructions. For case for this stretch interfacing – I can read that it tin can exist used "for light to medium weight knits, wovens and sweater knits". And likewise if y'all are using a commercial blueprint you tin read blueprint didactics about the interfacing you demand to use for the project.

Some other thing to consider is the corporeality of stiffness you want.

So if you lot take a few dissimilar types of interfacing yous tin examination your fabric and see what works the all-time for your projection.

Popular Brands of fusible interfacing

Information technology can exist sheets, rolls, or small tapes. They sell information technology by the yard in fabric stores, or by packaged sheets or rolls. The nigh well-known brands are these:

- Pellon

- Bosal

- Clover

- Heat 'n Bond

- Steam-a-Seam

At that place are some specialties in the world of fusible interfacing.

There are some companies that sell patterns together with printed fusible interfacing – full-size panels of cut lines and sewing lines printed on fusible interfacing and then you can complete a project easier. One of the brands is called Quiltsmart. People say that "Printed interfacing eliminates curved piecing, and is faster, easier, and more than accurate than templates, tracing, or freezer paper. These patterns are designed for all quilters, from novice to expert."

Another specialty interfacing is fusible with a filigree or dots and then you lot can trace a design onto it. Or it can be perforated.

At that place are also precut fusible interfacing pieces – pre-cut for waistbands or purse straps.

So hither is my YouTube video. Check this out if yous like to come across how to utilize fusible interfacing instead of read…

Do y'all make these 15 mistakes with your serger?

Enter your email in the box below to download your free eBook and discover out which mistakes you should avert!

Subscribe to my weekly newsletters with sewing tips and tutorials, free sewing patterns, printable PDFs and other useful content and y'all'll discover the eBook in your inbox.

Subscriber exclusive offer.

Did you find this tutorial helpful? If so, salvage this pin (meet below) on your sewing board so you can come to this tutorial subsequently when you are ready to use fusible interfacing, and follow me on Pinterest for more than tips, tutorials, and inspiration!

Ready to take the side by side step in your sewing journey? Check out more footstep-by-pace tutorials from my weblog and don't forget to share!

How To Get Blendall Repair Sticks Out Of Fabric,

Source: https://www.ageberry.com/how-to-fuse-interfacing/

Posted by: kinmanbobbled.blogspot.com

0 Response to "How To Get Blendall Repair Sticks Out Of Fabric"

Post a Comment